Injured VW Worker: ‘This Is Why We Need a Union’

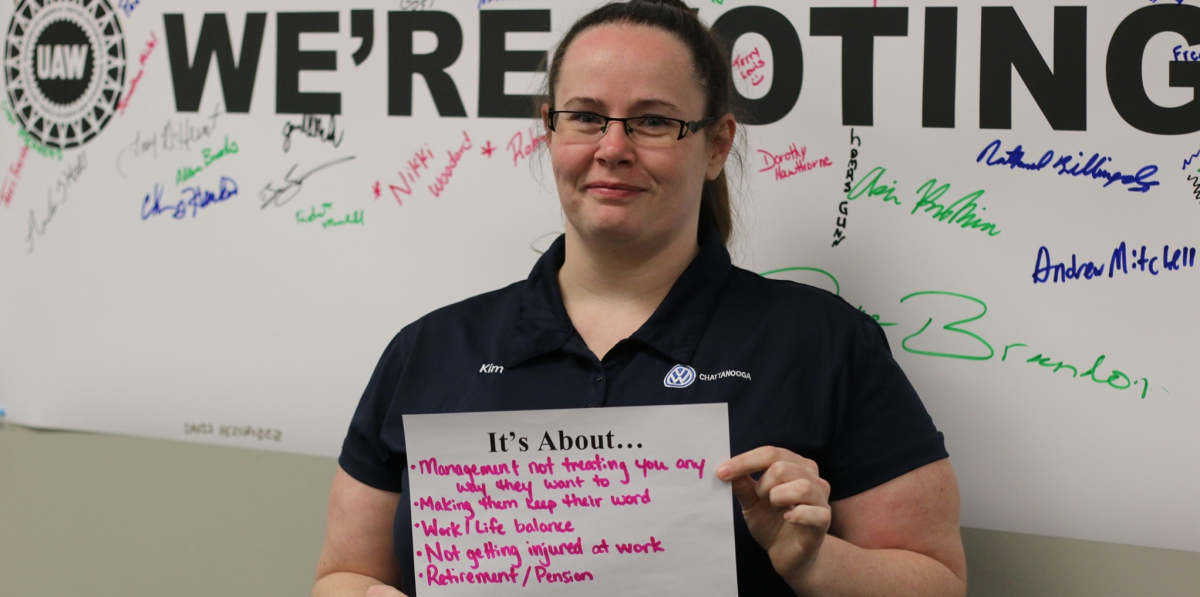

Chattanooga Volkswagen worker Kim Onofrey is supporting the union drive. "Nobody should have to go through what I went through—not for a job," she wrote. Photo: UAW Local 42.

On-the-job injuries are rampant in auto factories, where many dangerous tasks are still done by hand and in a hurry. It’s one of the main reasons why workers are organizing a union at the Volkswagen plant in Chattanooga, Tennessee. The vote begins June 12. Here plant worker Kim Onofrey describes what happened to her. –Eds.

I was working on the metal finish line that repairs defects on the bodies of the vehicles before they go to the paint shop.

Part of the process is to lift the hatches from closed (at thigh level) to fully open (over your head) to check for and repair things like weld expulsion or dents.

This is before shocks are put in the hatches. They are bare metal. There is no lift assist.

To keep the hatch open, you prop a metal pole inside. This is supposed to be done in pairs, with one person on each side of the car.

But that rarely happens. Most often one person is running behind, and because of the “Don’t stop the line!” mentality, the other person lifts the hatch alone. You have to have the pole ready in one hand, leaving just one hand free to lift the hatch.

When I injured my shoulder, I had been paired with the same person for a week. I was always done faster, so I was doing the majority of the lifting.

I think it started out as a repetitive use injury, and the lack of proper treatment made it worse. I had been doing the job for 11 months.

I marked an X on their little sheet to show my discomfort, like they have us do. But it was the middle of the next week before anybody from Progressive Health, the onsite medical clinic, came down to check on me. I was given the standard regimen: “Do these stretches, ice it, and take Ibuprofen.”

I continued to work through the pain. Maybe two weeks later, after a night when I couldn’t even lift my arm, I texted my supervisor that I needed to go see the doctor.

‘YOU’RE FINE’

I went to the onsite clinic before my night shift. They gave me the option to see the doctor who was there that day, or to wait for an appointment with someone I could choose from a list. The pain was unbearable, so I chose the doctor there.

That was where I messed up. It was 5 p.m., and the doctor was in a hurry—on top of being your standard company doctor who has a poor bedside manner and treats you like you’re not actually hurt. He moved my arm around a little, and despite very audible cracking and grinding, he said I was fine.

He wanted to see if some time off would help—the winter shutdown was coming up, almost three weeks off work. I was sent back to the line with no restrictions, and with instructions to do some physical therapy exercises with people in the clinic.

But it didn’t take an hour of being back at work in January after shutdown for me to know my shoulder was definitely not better. They continued to make me do the therapy and finally made me a doctor’s appointment for the end of January.

A few days before the appointment, my shoulder popped on the line while I was bringing a hatch down.

SUPPORT LABOR NOTES

BECOME A MONTHLY DONOR

Give $10 a month or more and get our "Fight the Boss, Build the Union" T-shirt.

After that pop I was unable to do even simple things. I couldn’t hold my tray in the cafeteria without feeling like my arm was going to dislocate. My team leader took me to do offline work until my appointment.

When I finally saw the doctor, he was like a different person. After hearing the same grinding and cracking in my shoulder, he finally put me on work restriction and ordered an MRI.

I had to see a specialist for the results; the specialist had to send me to a different specialist. Finally on April 23 of that year, I went into surgery.

SLOW AND PAINFUL

The procedure was supposed to take an hour. It ended up taking three and a half hours because the damage was so serious. And after that, I had to keep my shoulder immobilized for a month, and do physical therapy for another five months.

Recovery was much more difficult and painful than I had imagined. I also hadn’t imagined how incomplete it would be.

It was four and a half months before I could sleep in the position I always used to. I still have trouble rolling out of bed on my left side or pushing up from my stomach. My arm buckles under the pain.

My shoulder still hurts every day—mostly mild, but always there. I can’t reach high enough on my back to put a bra on in the normal way, and they say I may never be able to.

Swimming isn’t as enjoyable as it once was, and it looks like my kayaking days are over. I always wanted to learn rock climbing, but I’ll never be able to pull or hold my own weight up the way you need to for that.

My injury affected me in a lot of ways that I wouldn’t have guessed. When I struggled with what I used to consider basic tasks, it really made me question my self-worth.

Physically, I became very guarded. When I’m in a crowd I have to protect my shoulder so that nobody bumps into it. I flinch when someone pats me on the shoulder.

Is it improved from before the surgery? Yes, but it took a full six months before I began to feel like it was worth the painful recovery.

And at a year out, this is pretty much as good as it will ever be. Meanwhile I’m back to work in another area of the same VW plant.

Nobody should have to go through what I went through—not for a job. This is why we need a union.

Kim Onofrey works at the Volkswagen plant in Chattanooga, Tennessee.