Safety: Bosses Want to Fix the Worker, Unions Want to Fix the Job

Workers at a union safety training drew a workplace hazard map together, back when sitting close was safe! But drawing such maps separately and then comparing them, at a healthy distance or in an online meeting, is still an effective strategy to start organizing for a safer workplace. Photo: NJWEC (CC BY-NC-ND 2.0)

Unions and bosses have different outlooks on safety. Employers say illnesses and injuries are caused by worker carelessness: he didn’t wash his hands enough; she touched her face. That’s the way the boss wants you to think, too.

But the union realizes that it’s the hazards themselves that cause injuries, and that it’s the boss who sets up the workplace, either designing in hazards or failing to design them out. The boss has everyone work in the same tiny space. The boss won’t install a cough guard between you and customers. Emphasize these different outlooks with workers.

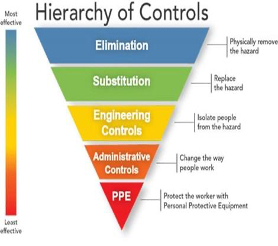

Bosses want to fix the worker. Their only way to reduce illnesses and injuries is to require gloves and other personal protective equipment (PPE). They focus on getting workers to work safely by threatening discipline and punishment. Now there are shortages of PPE and they have no other ideas.

The union wants to fix the job itself. Identify and eliminate hazards. Reduce existing hazards with engineering controls like improving ventilation or safer procedures, and move people away from each other.

The boss wants workers to think about safety his way. But workers become passionate when they start thinking about safety like unions do. Injuries turn from “I did something stupid” to “The boss did this to me.” Now more than ever, safety is ripe for organizing.

Familias Unidas por la Justicia (Families United for Justice), a farmworker union, is using the way they are forced to work close together and the lack of sanitation to organize berry workers in Northwest Washington. The Border Committee of Women Workers is promoting discussion of lack of ventilation and tight working conditions in the maquila factories on the U.S. border to organize.

WORKERS HAVE SOLUTIONS

The boss can’t or won’t figure out how to reduce or get rid of hazards, so we have to show him how. Solution mapping is an easy, participatory activity that finds hazard controls fast. To start, discuss the types of controls below.

- Elimination: The best way to control a hazard is to eliminate it. If you can work from home, for example, you won’t be exposed to sick customers or workers.

- Engineering: These controls protect workers by removing hazards or by using a barrier to keep the hazard away. Clear cough shields in front of a cashier are engineering controls.

- Procedures and Training: Change the way you do the work. Instead of swiping the customer’s credit card, have them do it themselves. New procedures require training.

- Personal Protective Equipment: PPE protects only the user. Gloves and N95 respirators (often called masks) are PPE. PPE is usually the least effective way to protect workers, but if better solutions don’t completely eliminate the hazards or while they are being installed, PPE may be essential.

Note: Masks, such as cloth or surgical masks, are not PPE. Those masks do not protect the wearer because they leak. They only protect the people around the wearer by catching coughs and sneezes. It’s like coughing or sneezing into your arm. Those masks are more like engineering controls.

Assign each control type a shape or a color. Then each worker should draw a workplace map and use the shapes and colors to show where controls are needed, and what kind. When one worker explains their map, people who work in the same area can suggest additions and improvements.

You can do this during an online (Zoom) or phone meeting or in person while maintaining a healthy distance.

It’s amazing how many solutions workers may come up with after the boss said the respirators he couldn’t get were the only solution. People should keep their maps so they can see how things progress.

SET UP A WORKERS’ SAFETY COMMITTEE

This is not the employer’s safety committee. It’s all workers. Hold some open sessions where you start a buzz with training about the union view versus the company view of safety. Then make solution maps.

Choose which issues to work on. Prioritize solutions that affect a lot of people, especially workers who are on the fence about the union. Areas with high exposures should be high on your list, but pick some easy and quick-to-do solutions too.

SUPPORT LABOR NOTES

BECOME A MONTHLY DONOR

Give $10 a month or more and get our "Fight the Boss, Build the Union" T-shirt.

Make sure your solutions are specific about what you want. Don’t let the boss implement something that destroys solidarity. Make sure you get everyone’s contact info for follow up.

SHOULD YOU CALL OSHA?

OSHA complaints can have serious drawbacks. First of all, OSHA has no specific regulation saying employers must control exposures to coronavirus and it refuses to develop one. As of April 24, OSHA has not cited any hospital for anything related to COVID-19.

OSHA has also said it is temporarily not going to enforce some of the standards it does have, such as mandatory annual respirator fit testing. (See here.) Under Trump, OSHA’s emphasis is cooperation with employers, not enforcement. Without a citation, the boss claims he’s got a clean bill of health. In any case, OSHA has six months to decide whether to cite the employer or not. When it does, its average penalty for a serious violation is under $3,000. (For details on how OSHA is addressing coronavirus precautions in workplaces see here.)

Even in typical times, usually it’s better to just threaten to call OSHA. Employers really don’t like dealing with OSHA. They’ll have to drop everything they’re doing the moment OSHA walks in; it takes up a lot of time and energy. Most employers are at least a little afraid of the outcome. Employers would much rather deal with their employees. They don’t realize how much control you can have.

Bottom line: Don’t expect OSHA to swoop in and solve the hazard in a timely way. But threatening to call OSHA can be a tactic to show that you know your rights and push your boss to take your concerns seriously.

USING SAFETY STRATEGICALLY

Present your list of solutions to the boss. The boss will likely fix some easy stuff. Tell everyone! The union is already helping the workers! Remind workers that the remaining problems are why they are organizing (and if your workplace isn’t yet unionized, why you need a union contract).

Pass around the solution map. Show the workers all the problems the boss won’t fix. Maybe leave a few copies in public places for the boss and customers to see.

Have workers take pictures of coronavirus hazards. The boss will complain, but banning taking pictures is an unfair labor practice. Publicize the “Hazard of the Week.” Do inspections and publicize the results in the worst areas. Tell your fellow workers and go to the media. Right now they are interested in doing stories about workers at risk.

Pass out “At Risk!” stickers for workers to wear where they might be exposed.

Distribute a safety complaint form to be returned to the safety committee. Deliver copies to the boss with a deadline to respond. Publicize! Publicize! Publicize! Again, think about going to the media.

Take matters into your own hands. If workers come up with a better procedure, don’t wait for the boss to implement it. Have the workers implement it together.

For instance, letter carriers in Winnipeg rearranged their mail sorting area so that workers would be more than six feet apart. UPS Teamsters in New York found their own source to buy masks for workers, then pushed the company to buy them. Bus drivers in Seattle blocked off the area around them to keep passengers six feet away.

The coronavirus pandemic is like every other issue in the workplace. There are organizing opportunities, albeit grim ones. Let’s use them!

Jay Herzmark is an organizer on workplace safety issues.